I am a Research Chemist in the Analytical Branch of the Chemistry Division at the US Naval Air Warfare Center Weapons Division (NAWCWD) in China Lake, California. I run my own research group as well as a number of centers including our Mass Spectrometry Center, our High Throughput Robotic Screening Center for Advanced Energetic Materials, and our Division’s Rapid Prototyping Center. These centers provide customers with novel solutions to Naval problems, primarily in the propellant, explosives, fuels, and pyrotechnic area, as well as supporting a variety of missile programs.

My research group focuses on three major areas that are intertwined; energetics, environmental analysis, and mass spectrometry. Our explosive portfolio explores several ways of performing synthesis through microdroplets and thin films, exploring new reactor designs to improve these synthetic methods and scale them to larger reactors, incorporating robotics into automated synthesis and formulation, and finally adding process analytical technologies (PAT) into synthetic steps. Our environmental portfolio is split between thermal destruction analysis of both emerging contaminants, such as per- and polyfluoroalkyl substances (PFAS), and pyrotechnics, in-situ PAT for remediation monitoring, new photochemical remediation methods, and finally in-field detection.

The portion of our laboratory focused on in-field detection leads to the core of this article. We have developed a new ionization source called 3D-printed cone spray ionization (3D-PCSI), which we couple to field portable mass spectrometers for in-field environmental and threat detection work.

What role does analytical science play in national defense?

Analytical chemistry is crucial to national defense. Some of the common and routine roles include quality assurance and lot acceptance tests for chemicals that will be used for propellant formulations or standard analytical chemical confirmation for our brilliant synthetic chemists. There are also a number of threat detection systems that are crucial to national defense and protecting our warfighters, such as threat detection systems to combat chemical, explosive, biological, radiological, and nuclear incidents.

Some of the more interesting areas that I have had the pleasure of working on since starting at NAWCWD include running chemical analysis on weapon systems pulled from the fleet to ensure lifecycle specifications, surface analysis of microelectronics to ensure genuine parts for our various systems, and sampling at ranges to ensure the tests did not release any toxic materials into the environment. There are also the always fun conversations: “Pat, we found this [insert physical state here] [in an old bunker, on the range, in a vehicle]. Can you tell us what it is so that we can proceed with […]?” Analytical chemistry is key to so many areas and is a reason NAWCWD constantly invests in our people and instrumentation to make sure we have world-class facilities.

What are the unique advantages – or challenges – working at NAWCWD?

As noted above, NAWCWD has a lot of varied analytical science work and it is a great place to do analytical chemistry. One challenge as a DoD laboratory is that we have to strike a fine balance with information that we can publish in the open literature and what is kept proprietary. This at times can make postdoc recruitment challenging; however – shameless plug – I have five postdoc billets open currently!

Another challenge is the location of NAWCWD, which is relatively remote due to the testing that occurs here. Most people who succeed here have an appreciation for the outdoors/hiking/dirt biking, and so on because we are close to amazing trails, mountains, and ski resorts. The final challenge: though there is great academic freedom, most research is focused on the global Navy or DoD mission. Most times when we stumble across an interesting idea that may not align with our mission, we try to collaborate with academics to make sure we are still making these scientific advances while still keeping our day-to-day focus on the NAWCWD mission.

Those minor challenges are completely overshadowed by the major advantages. The first major advantage of working at NAWCWD is definitely the instrumentation. We often say, “We are instrument rich and people poor.” When I started four and half years ago at NAWCWD, the mass spectrometry laboratory had three mass spectrometers. Today, we have replaced them all with newer systems and we now have 21 mass spectrometers and are still growing. We have almost all capabilities that any mass spectrometrist could want and my analytical colleagues that run other centers would say the same about their instrumental specialties. Similarly, the rapid prototyping and high throughput robotics laboratories have been set up in the last few years with significant investment. A second advantage is for the analytical chemists who do not necessarily want to lead a group or write research proposals, there are a number of positions at NAWCWD for analysis. Another advantage is the access we have to some interesting research topics that usually aren’t done in academia due to safety concerns, such as novel explosives research. It is because of the analytical support facilities at NAWCWD that we are able to perform research in these wonderfully obscure areas.

Finally, we have world class scientists that we get to interact with daily. On my first day at NAWCWD I was introduced to Dan Harris – the author of Quantitative Chemical Analysis. His office was three rooms down from mine!

Tell me about your research into 3D-printed cone spray ionization-mass spec…

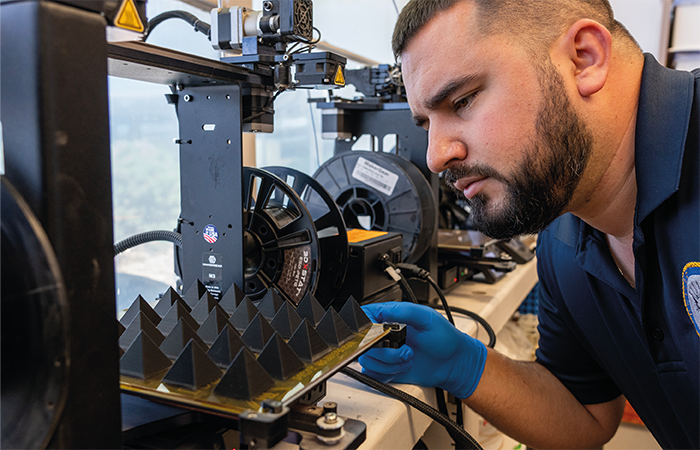

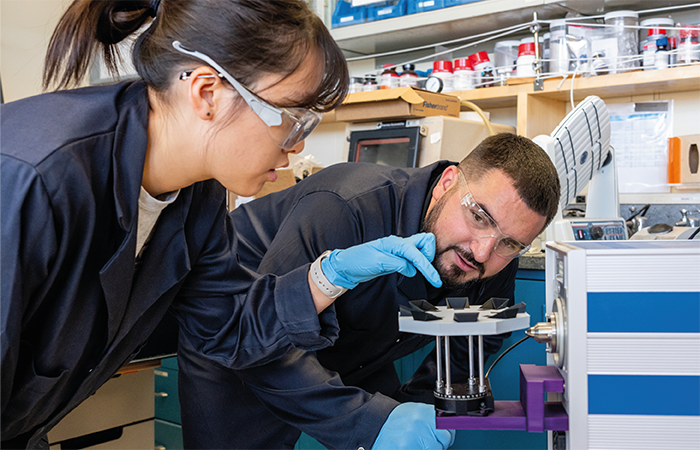

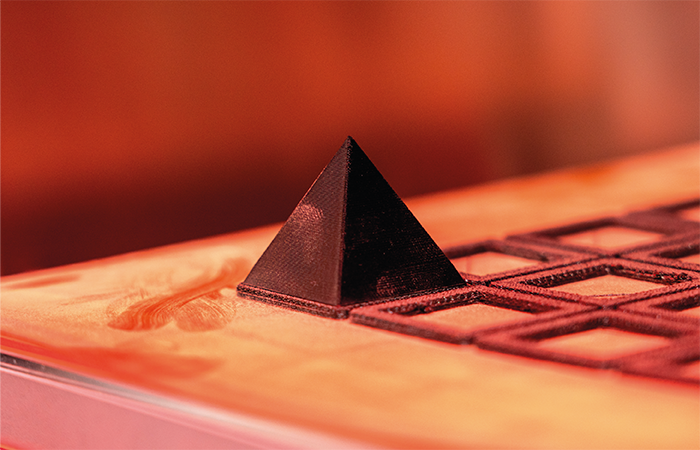

We developed 3D-printed cone spray ionization – mass spectrometry (3D-PSCI-MS) as a rapid, reproducible, and low cost analysis method for bulk solids and trace analytes within bulk matrices. Printed with conductive plastic, the cones for 3D-PCSI have a ~100–200 µm hole at the tip. Solid material is scooped/placed within the cone, extraction and spray solvent is added on top, and then high voltage is applied. An electrospray-like Taylor cone is formed at the tip of the cone, where the analyte of interest is ionized but the bulk matrix, such as dirt, is trapped within the cone.

The idea for this ion source was drawn from my experience at Purdue University with Graham Cooks. At the time, we were doing forensic analysis with paper doped with nanoparticles that acted as a single sampling substrate for paper surface enhanced Raman spectroscopy and then paper spray ionization (PSI) mass spectrometry. This method worked well for trace drug analysis but there was a need for a method for bulk drugs. Around the same time, Purum Kim and Sangwon Cha at Hankuk University of Foreign Studies in Yongin, Korea, published their ionization source paper cone spray ionization (PCSI). PCSI seemed to be the answer to this problem for bulk analysis.

One of my last projects at Purdue University was a chemical education experiment that taught undergraduate senior analytical chemistry students these dual techniques, either pSERS and PSI-MS for trace drug analysis or PCSI-MS and traditional Raman spectroscopy for bulk drug analysis. During the experiment, the students had a lot of trouble folding the cones into an optimal geometry for proper spray. Even when the teaching assistants folded the cones for the students, they still had trouble positioning them due to differences in sizes – and some of the students even bent the tip on the cone.

By this time, I already knew I was going to be working at NAWCWD, and I was now questioning if there was a better way of doing a cone spray based technique that would be more rugged and reproducibly shaped. Around the same time, I had been aiding Adam Hollerbach on his project involving a 3D-printed ion mobility spectrometer. Adam taught me a lot about 3D-printing and working with him I thought a conductive plastic cone may be the way to go!

The result – 3D-PCSI-MS – is rugged, reproducible, and made with commercially available polymers.

What challenges did you face during the development of 3D-PCSI-MS?

Since this is an external ionization source, the major concern is chemical compatibility. The carbon nanotube doped PETG filament that we routinely use is really robust for most ambient ionization solvents. We knew this from past ion mobility work and a simple literature search; however, it was a major issue brought up by reviewers when publishing our first manuscript on the technique. We were rejected from the first two journals – the major concern was the plastic compatibility with the solids and the solvents. It was frustrating because these chemical compatibilities are out in the open literature and were not a major concern at all – in my humble opinion! Luckily, the reviewers at Chemosphere saw the value and published the first manuscript. As a matter of fact, for the third manuscript on 3D-PCSI, we actually ran chemical compatibility tests for most of the conductive plastics just to have a peer-reviewed reference to point to. We are currently working on more exotic plastics and high-temperature polymers and are examining chemical compatibilities and benefits of some of these “super polymers.”

The second challenge for the initial development was funding for the device. The project started from NAWCWD internal Ignites funds, which are “shark tank style” seed funds. Most of the microfunds went to purchasing the printer, filaments, chemicals and other supplies. There was only a small amount of research and development funding for this original project. Luckily, this led to excellent collaborations to maximize the effort on the limited funds with other scientists, including Christopher Mulligan at ISU, Elizabeth Dhummakupt and Daniel Carmany at Army DEVCOM CBC, Ryan Bain at ATF, and finally our wonderful Naval Research Enterprise Internship Program (NREIP) summer interns. I would also be remiss if I did not call to the attention the tremendous effort of two post-doctoral scholars, Hilary Brown who was the driving force for the testing and development of the cones, and later Brian Molnar who supported many of these projects.

Now that we have successfully demonstrated 3D-PCSI-MS for a number of case studies and taken the technology from basic research to a demonstration and evaluation technology, we have projects funded by Navy Environmental Sustainability Development to Integration (NESDI) and Army Engineer Research and Development Center (ERDC) programs, which helps with this technology development.

We are now trying to commercialize this technology, which brings a new area of challenges that have been fun to start to tackle.

What specific DoD applications do you envisage for 3D-PCSI-MS?

We have demonstrated 3D-PCSI-MS coupled to field portable mass spectrometers for the analysis of PFAS, explosives, chemical warfare agent simulants, live V-agents, and drugs of abuse.

The major benefit of 3D-PCSI-MS? If the solid fits within the cone, we can extract the analyte of interest and spray it into the mass spectrometer. In a manuscript that is currently under review, we demonstrate this with soils, tree bark, newspaper, rubber from a boot, jeans material, cloth, grass, flowers, bottle caps, and leather from a wallet that were all contaminated with chemical warfare agent simulants. 3D-PCSI-MS is extremely rapid and can be used for environmental field mapping, such as PFAS contamination, which is currently a major concern for the DoD, or for rapid threat detection. Some of the work that will soon be coming out of our laboratory will also add to the capabilities of 3D-PCSI – so be on the lookout in 2024!

Do you expect to see more groups attempting to 3D print mass spec components?

We actually frequently use 3D-printing in new microdroplet/thin film reactor development. We also support other groups by making fast prints for projects so they can visualize their part before they send it off to get it precision machined.

I have been amazed at my summer NREIP interns, specifically TJ Pinedo and Caleb Potter, and how extremely proficient in 3D printing they are – most started as hobbyist printers. I can vocalize an idea and I will have 10 prototype designs on my desk by the end of the week. I think 3D-printing and CAD design will soon be a required course in college science degrees because of its potential across all scientific fields.

The major benefits of 3D-printing are the capability to rapidly prototype custom parts on demand for a low cost. The low cost of 3D-printers has also made the technique more appealing across the academic landscape. At American Society for Mass Spectrometry (ASMS) 2023, there was even a display in the main convention center covering all the 3D-printed parts and devices that participants had developed over the last year! That’s how you know it is being picked up globally.

One of the final advantages that comes to mind is the reproducibility of 3D-printing. Many manuscripts are adding the CAD files to the Supporting Information so other groups can use their setups. I have always admired Robert Winkler’s 3D-printed low-temperature plasma probe manuscript, and all of the detail he provided for others to use. Gone are the days when you needed a ring stand, clamp, and a copper clip to do ambient ionization, with most of the error coming from hand positioning the ionization source. Most groups I visit or collaborate with have some 3D-printed part to make analysis easier. We even 3D-print the pressure pin overrides for more recent mass spectrometers that companies have added to prevent individuals from using non-commercial sources…

Any plans to continue this work?

Yes! We have four manuscripts with 3D-PCSI in for review currently and two manuscripts going through the Navy release process for novel reactors that incorporate 3D-printing. We have been expanding our printing capabilities and have been collaborating across NAWCWD more frequently to aid in other projects. Our lab has expanded from the traditional benchtop FDM and SLA printers into high temp FDM polymers and are seeking to transition into metal printing as well!

Image Credit: NAWCWD