- Ease of use is key. Nowadays, many laboratory scientists using LC are not analytical scientists by training. We need to get these non-experts using the equipment more efficiently by improving workflows, making software easier to use, and cutting the time taken at all stages. I’d like to see the intelligence and the experience of analytical chemists distilled into the software, so that users no longer have to be experts. The ideal would be to do everything within one package. We’re not there yet, but we’re heading that way. Even troubleshooting could be automated to some extent, with instrument software suggesting potential causes for unusual results.

- Robustness underpins efficiency. You’ve got to be able to rely on your results, and trust that they won’t change from one run to the next. You also need your instrumentation to work efficiently to avoid downtime.

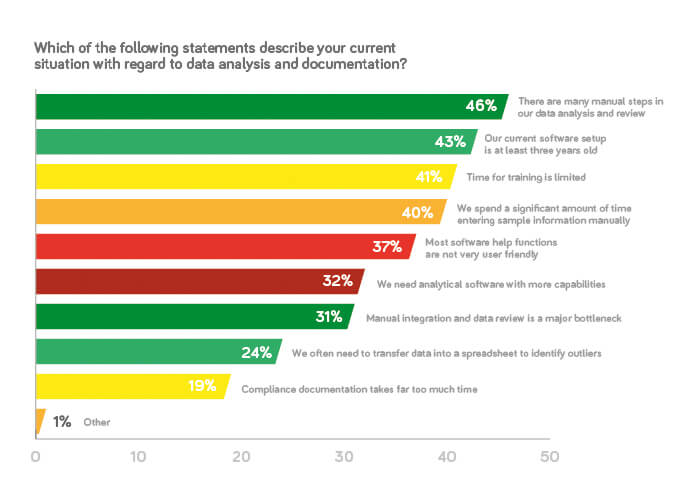

- Find time for training. When it comes to implementing new software, 41 percent of respondents in a survey of 1,200 LC users reported not having enough time for training. To me that’s a false economy. If you have software that’s capable of doing your data analysis, why wouldn’t you learn to use it and save time down the line? You may lose a day in training but, if you save three weeks over the year as a result, it’s well worth it. This is true of instrumentation too – there are often lots of ways of saving yourself time and effort that you can easily find by studying the manual or asking an engineer.

- Sometimes, it’s about getting the basics right. If your instrument is not performing as you’d like, start by testing the simple, inexpensive parts of your system. For example, check you’re using the right column chemistry, solvents and consumables.

- Prevention is better than cure. One way to minimize downtime is to carry out regular system suitability testing, so you can spot problems early.

- The most efficient way isn’t always the fastest. I define efficiency by how useful your results are, balanced against the input required. If you spend an extra hour or two to get a better result it’s not necessarily inefficient. You have to ask yourself: is it more efficient to save time but only complete 90 percent of a project, or spend a little more time and complete 100 percent?

Software

There are already some interesting software applications that can guide you to the optimal method for your sample. At present, you need to have a good level of understanding to be able to use the software – if you ask the wrong question, you will get the wrong answer. I predict in future we may have more intelligent software that can define the inputs that are needed and all the parameters that should be studied, so that we are less reliant on human input.

Automation

Automation is a big trend in industries such as biopharmaceutical manufacturing. The ideal is a line that takes a sample from your reactor to your instrument automatically every few minutes and confirms that all parameters are within acceptable limits. If a problem occurs, production is halted automatically and staff are alerted.

Sample handling

Using barcodes to track samples is still rare amongst the labs I visit, but I believe that as we start to see off-the-shelf systems becoming available, we will see greater uptake of this type of tracking system.

Troubleshooting

Already, a lot of instrument software offers some hardware failure identification, and will alert you to problems with pump pressure, potential leaks, blockages, and so on. But once you get into chromatographic issues, such as peak distortion, it’s still largely down to experience – again, that’s something that may change as software grows increasingly sophisticated.

Final thoughts

Regardless of how technology advances, it’s important to keep things simple. For example, if you have a choice of mobile phases, use the simplest that is fit for purpose – it will be much more robust. And don’t be afraid to try an entirely different approach, rather than persevere with a technique that is simply not suitable.

Are you a scientist, laboratory analyst or lab manager – or all of the above? Are you willing to challenge your perception of efficiency or do you already know you need to make efficiency gains?

Join our experts – Kelly Zhang, Udo Huber, Stéphane Dubant, Wolfgang Kreiss and Oliver Rodewyk – for an exclusive series of video webinar masterclasses:

Webinar 1 – Analytical efficiency: How to push your results to the next level by selecting suitable technology

Webinar 2 – Instrument efficiency: How to survive the sample onslaught and even create a little breathing room

Webinar 3 – Laboratory efficiency: How to plan for success and secure your future

For more details, click here.