Oliver Rodewyk has been in the chromatography business for 32 years and is now a strategic account manager in the service sales division at Agilent. Here, Oliver offers advice on boosting efficiency in labs – old and new…

When considering laboratory efficiency, you should always start with a critical reflection of where you are today. Also, keep in mind that equipment is not the only important factor in efficiency – your team members are the ones who will drive improvement. Are they trained in the best approach to the task? Are they open to change? It’s crucial you have the right people, with the right training, at the right time.

An “old” lab

- When inheriting an existing lab where much of the equipment is outdated, the priority for laboratory managers should be to identify critical systems and target investment to those areas.

- Don’t do all your upgrades at the same time, but stagger them to spread the cost and avoid having multiple parts due for replacement at the same time in years to come.

A new lab

- When setting up a new lab, the most common mistake I see is to take a “copy and paste” approach – assuming that if it worked perfectly in the past, it will work in the future.

- Instead, use a “copy and adapt” approach that builds on a foundation of past facilities, but invest at least 10-15 percent of your time and capital on adapting to new challenges and looking for ways to evolve or develop the lab.

How will you survive in an increasingly competitive world? Our survey discovered:

- 1 in 3 labs is under competitive pressure

- 1 in 5 labs is viewed as dispensable

- 1 in 5 labs is already in direct competition

Wolfgang Kreiss is an independent consultant in laboratory management, working on strategic and operational projects for analytical laboratories in industry and government agencies. Here, Wolfgang helps you take the first step towards efficiency gains…

- To improve efficiency, you must first quantify it – and that means considering how best to assign numerical values to various efficiency parameters.

- You could think of efficiency as a simple ratio between input (amount of work, operating costs) and output (number of analytical results, timeframe or monetary value); this gives a firm basis for comparing efficiency with different setups.

- The laboratory is a very complex unit – it’s not enough to simply collect numbers for the various efficiency parameters, you also have to look at all the possible influences that might affect the numbers.

- It’s not easy to measure efficiency – do not be afraid to seek external support!

Our survey revealed that respondents are often challenged to improve throughput and do more with less.

- 64 percent said they would benefit from shorter LC run times.

- 44 percent said that sample numbers are increasing – but staffing levels are not.

Martin Hermsen is a senior R&D analyst in the organics department in the Eurofins environmental lab based in The Netherlands, where he is in charge of technical aspects of data automation and robotics. Here, Martin shares his approach to making efficiency gains…

- To improve efficiency in any lab, one of the first things that I do is go to the work floor and look at the process.

- Talk to the staff. You may think that you have the ‘right way’ of doing something, but remember to consider the people who must do a particular task day in, day out. It’s best to adapt to their experience and preferences wherever possible.

- I sometimes get insight from someone that has no lab experience; I ask them to look at the process with a fresh pair of eyes. Often, it brings up things I have never thought of.

- Look at the bottlenecks in your workflow – seek ways to remove them

- Where is the most downtime occurring? Think about where replacement systems would be most impact.

- Consider introducing automation – it can be a very powerful tool. Robots can take over the time consuming, low-skilled aspects, leaving staff free to focus on more complex issues.

- Above all, don’t stand still.

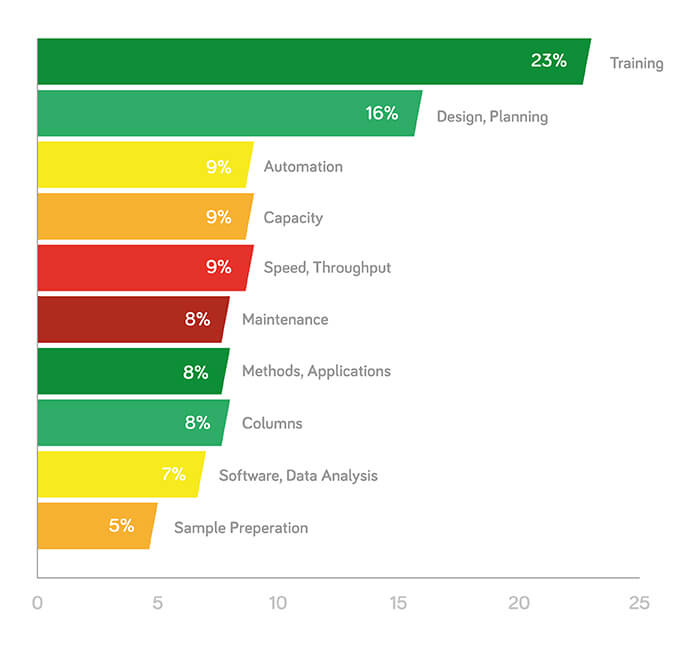

Figure 1. Where have you made successful gains in laboratory efficiency?

Nearly 60 percent of respondents said that they only upgrade equipment when it no longer meets requirements. The instrumentation in one in five labs already fails to meet expectations!

Nearly half (45 percent) of respondents do not calculate return on investment or net present value for lab investments.

“When you need to replace old instrumentation, it can be useful to consider the value being generated by each instrument or workstation before assuming on the right purchase path. And it is certainly well worth the effort to gain an understanding of the true value of each purchase. However, there are challenges in making these calculations, not least that it’s surprisingly hard to get valid data. Add to that the many different definitions for return of investment and it takes experience and knowledge to understand which are appropriate, so I would recommend talking to someone from a business management or controlling unit.” – Wolfgang Kriess

A simple question, but ask a room of laboratory managers and you’ll get a surprising variety of answers. We’d like to know your definition of efficiency – get in touch at charlotte.barker@texerepublishing.com. To get you started, we asked our experts to weigh in with their own definitions…

“The ratio between the output of a lab and the required input. This could be as simple as the number of tests per day or a more complicated metric, such as the value of results versus the lab operating costs.” - Wolfgang Kreiss

“The continued ability to successfully implement alternative workflows in the lab by optimizing human and technical resources.” - Oliver Rodewyk

“To me, it’s simply how many samples are processed, offset against the number of hours of labor.” - Martin Hermsen

Are you a scientist, laboratory analyst or lab manager – or all of the above? Are you willing to challenge your perception of efficiency or do you already know you need to make efficiency gains?

Join our experts – Kelly Zhang, Udo Huber, Stéphane Dubant, Adrian Dunn, Wolfgang Kreiss, Martin Hermsen and Oliver Rodewyk – for three video webinar masterclasses, now available on demand:

Webinar 1 – Analytical efficiency: How to push your results to the next level by selecting suitable technology

Webinar 2 – Instrument efficiency: How to survive the sample onslaught and even create a little breathing room

Webinar 3 – Laboratory efficiency: How to plan for success and secure your future

CLICK HERE to view video webinars