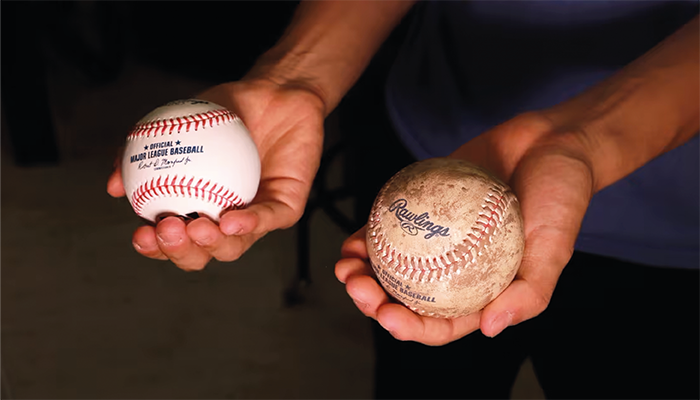

The magic mud is applied to every ball used in Major League Baseball, including in this year’s World Series.

Credit: Mark Griffey

A nearly century-old baseball tradition has finally been demystified: the unique “Rubbing Mud” used to prepare Major League baseballs owes its gripping power to a precise mix of clay, sand, and water. This special mud, sourced from a secret river location in New Jersey, enhances the texture and handling of baseballs – but, until now, the science behind its effectiveness remained unexplored. A recent study from researchers at the University of Pennsylvania reveals the mud’s complex composition and physical properties, shedding light on why it has become an essential tool for professional baseball.

The team investigated the material using rheology and tribology – techniques that assess flow and frictional properties – under conditions that mimic those in MLB games. Key findings indicate that Rubbing Mud’s properties stem from a specific balance of cohesive clay particles, frictional sand grains, and water content. These elements interact to form a substance that spreads smoothly, fills surface pores on the leather baseball, and increases friction when dried.

Rheological tests reveal that Rubbing Mud is a shear-thinning material, meaning its viscosity decreases as shear (or rubbing) increases. This allows the mud to coat baseballs uniformly, creating a smoother, more consistent surface. Confocal laser scanning microscopy (CLSM) and scanning electron microscopy (SEM) confirmed that the mud fills pores on the baseball, reducing surface roughness at larger scales while enhancing it at finer scales. Energy dispersive X-ray spectroscopy (EDS) analysis indicated a high proportion of silicates and clay minerals, such as quartz and mica, while atomic force microscopy (AFM) tests demonstrated that Rubbing Mud increases surface adhesion, effectively doubling it compared with an untreated baseball.

Tribological tests, simulating the frictional forces encountered when gripping or pitching, indicate that dried Rubbing Mud deposits sand particles on the ball's surface, further enhancing friction. At higher speeds, these sand grains can be sheared off, returning the baseball surface to a smoother state.

The study authors conclude that Rubbing Mud’s effects are not only useful in sports but could also inspire the design of sustainable materials with tailored friction and adhesive properties for applications ranging from construction to environmental safety.