Drawing inspiration from nature, Wee-Jun Ong – Professor of Chemical Engineering at Xiamen University Malaysia and the Director of the Center of Excellence for NaNo Energy & Catalysis Technology (CONNECT) – is developing artificial photo/electrosynthetic processes using nano- and photo-catalysts/electrocatalysts to produce clean hydrogen and energy-bearing fuels from water, sunlight and either carbon dioxide or waste plastics. His lofty aim? To help Malaysia – and the world – reach the net zero carbon emissions target by 2050.

To help facilitate his work, Professor Ong is collaborating with Agilent, which provides the instrumentation and know-how to help Prof. Ong and his team to understand and control the nanocatalytic processes he is developing, while characterizing reaction products, so that they can be repeated, scaled up, and eventually rolled out at a large scale.

Here, we speak with Prof. Ong to find out more about his fascinating research. Below, we ask Agilent’s Robin Philp (Academia & Collaborations Manager, South East Asia) why he’s so excited about the collaboration.

How did you begin working on energy-related applications?

My first source of inspiration came from my school studies, when I first learned about photosynthesis – how in plants chlorophyll absorbs light and carbon dioxide to produce glucose for the plant and oxygen, which we need for our survival. I’ve always wondered whether we might be able to reproduce this process artificially.

In artificial photosynthesis (also known as photochemistry), our “leaf” is a nanocatalyst that will absorb water, carbon dioxide, and sunlight to produce hydrogen – alongside other carbon-based molecules (CO, CH4, CH3OH and so on) – which could then be harnessed as a clean energy source. Essentially, this is what I’ve been working towards for the past decade and it continues to inspire me.

How do you break down your ambitious goal into more achievable tasks?

The end goal is to have a technological solution that can be commercialized and rolled out on a large scale, but, before you get to that point, there are a series of steps you must go through – from lab studies, to prototype, and eventually the industrial scale. One of the first steps for us was to try to understand the current bottlenecks in photochemical processes. In other words, how can we improve efficiency so that we are able to produce clean hydrogen from photochemical processes in large quantities?

I’ve always enjoyed trying to think outside the box, which means broadening your horizons and collaborating with others. So, I spent two years working as a Scientist in Singapore at the Institute of Materials Research and Engineering (IMRE), Agency for Science, Technology and Research (A*STAR), as well as several months on sabbaticals as a Visiting Professor in Germany at Technische Universität Dresden and the US at the Lawrence Berkeley National Laboratory, and the University of California, Berkeley.

Today, I head a growing team focused on using catalysts to sustainably produce clean energy or industrially relevant chemicals.

Which analytical questions arise during your work and how do you solve them?

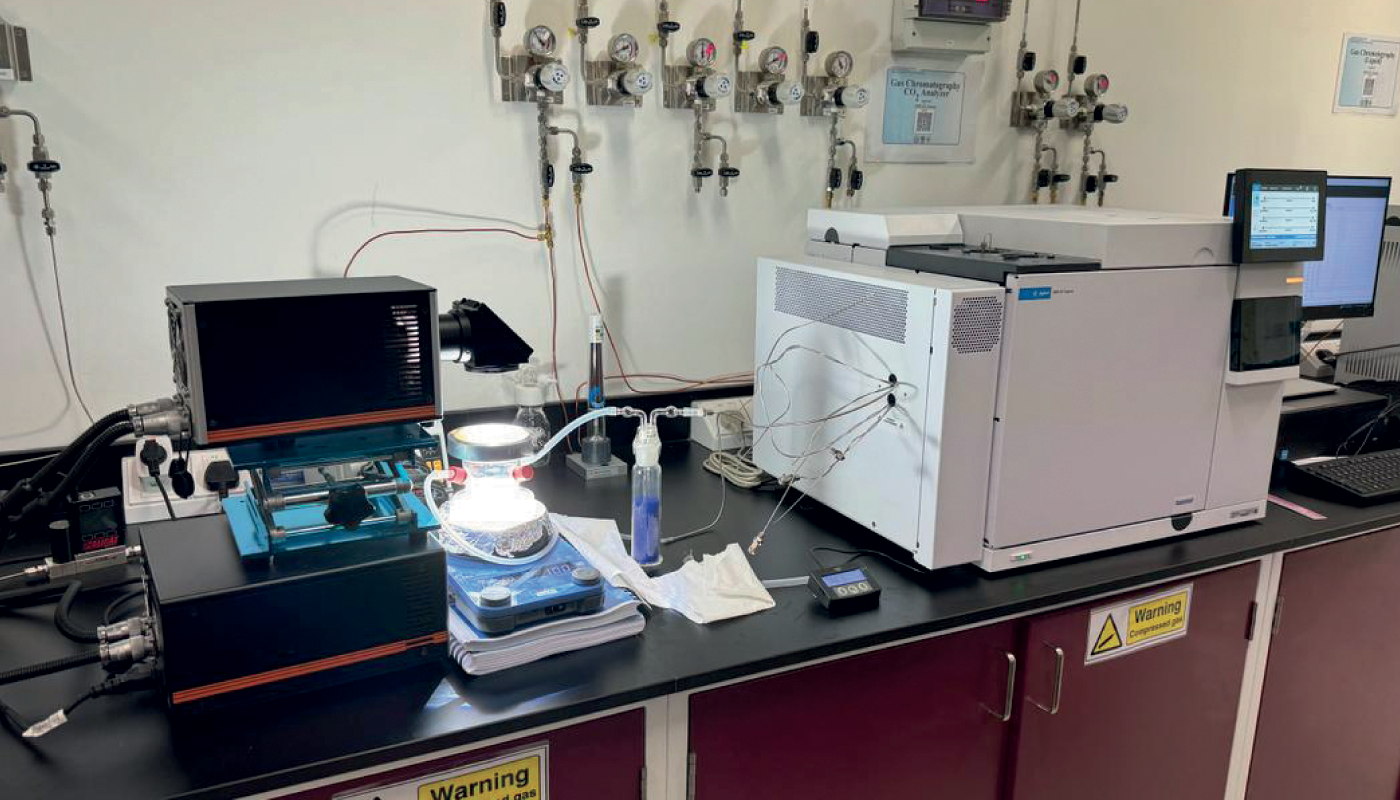

A crucial aspect of our work is understanding whether the catalysts we are synthesizing have the robust physicochemical properties for our purposes – converting carbon dioxide into hydrogen, methanol, and carbon monoxide, for example. To understand optical properties of our catalysts, we use UV-visible spectroscopy. But we also need to understand their structural properties, phase properties, and morphological properties to ensure that we – as well as other labs – can reliably repeat our synthesis process. For this, we use a range of analytical techniques – especially gas chromatography (GC), which has been my focus.

We also need to look at the hydrogen we’re producing, as well as the other chemical reactions from the carbon dioxide conversion that are taking place. We need to know what we’re producing, and how much, in order to comprehend the structure-activity relationship in the photochemical and electrochemical processes. This quantitative and qualitative task relies heavily on liquid chromatography (LC), which is a very important technique for my lab (despite me being known as a GC guy!)

How are you collaborating with Agilent in this area?

To be frank, I am an Agilent fan! I have been using Agilent products for many years – since I was a PhD student, when I used Agilent chromatography and spectroscopy systems. I also used Agilent systems at A*STAR. Once my own lab was up and running, I spoke with Robin about the possibility of working together more formally.

So, we are using Agilent products as part of our photochemical and electrochemistry work – but it goes beyond that. I mentioned the value of collaboration and broadening one’s horizons – this is why I sought out Agilent. For example, to quantify certain products from a photochemical reaction, you need to know which column is best suited to the products you are looking for. This is where we lean on Agilent’s expertise to understand which instrument to use, how to streamline the installation, optimize the method, and troubleshoot any issues. We have been learning a great deal from Agilent during this process.

Agilent Certified Pre-Owned Instruments deliver unmatched quality at an incredible value, at the same time, support green initiatives by giving renewed life to existing equipment. Experience Agilent Certified Pre-Owned Instruments Virtually now.

Certified Pre-Owned Instruments Virtual Experience | Agilent

In addition, we are also collaborating with Agilent in some other adjacent areas. For example, we have been looking at how we can convert plastic waste into valuable industrial chemicals – this part of the Malaysian government’s “Waste-to-Wealth” initiative to align with Malaysia's Plastics Sustainability Roadmap 2021–2030 as well as Hydrogen Economy and Technology Roadmap (HETR). We have found that we can produce hydrogen from plastic by a process known as photoreforming – using a photocatalyst to break plastic down in the presence of light. Here, we’re using Agilent HPLC systems to measure the liquid products from the plastic conversion. And given the wide range of different waste plastics produced and the variety of chemical conversions taking place, we’re increasingly using LC-MS systems to understand those pathways and ensure we have a high selectivity for the plastic conversion.

Going forward, we have a big project planned with Petronas – a petroleum company in Malaysia. Following the Malaysian government’s commitment to Net Zero Carbon Emissions by 2050, they are looking at renewable energy sources. And we are working with them on converting carbon dioxide using electrocatalysts. And there’s a strong possibility that we will produce liquid chemical products during the conversion, which would need to be characterized. It is very important to understand how much CO2 you are converting and which compounds you’re producing – which is where, again, the GC, LC (and LC-MS) comes in.

What is your “big-picture” vision for what you could achieve with your work?

Thinking about the next few decades, carbon neutrality will be huge. I don’t think it will be possible to completely replace natural gas or petroleum by 2050, but I do think we’ll have a mixture. And I think hydrogen will be part of that mixture – perhaps powering electric vehicles. I believe this is possible, but we need green, efficient hydrogen production – and that’s what we’re aiming for.

In the near term, we are in discussions with NanoMalaysia Berhad, an agency within the Ministry of Science, Technology, and Innovation (MOSTI), to show them that we can produce hydrogen from a catalyst using sunlight to power a fuel cell, which we can use to power a light in a special MADANI program. We will then roll out the technology as part of a pilot project in a village in the state of Johor to sustainably power streetlights. I’m incredibly excited about the prospect of our technology being applied commercially in this way; but it is, hopefully, just the beginning!

The really big picture is being able to produce clean energy on a scale that would allow us to achieve our sustainable development goals. To make that happen, everyone working on these technologies will need focus on collaboration – with each other, with technology vendors, with industry, and with governments. And that’s why I appreciate our collaboration with Agilent. Simply put, they have helped us make the necessary measurements to advance progress in our research.

Chemistry You Can’t Measure

With Robin Philp

What sparked your interest in the collaboration with Professor Wee-Jun Ong?

My role within Agilent is partly to establish collaborations with academia. We look for novel areas of research with significant impact potential – something that could ultimately benefit society. Of course, renewable energy has huge potential and we thought the work Wee-Jun and his team were doing was really exciting – even if he is at the early stages. It turned out that he had some technical and analytical requirements that we could help with, so the collaboration made perfect sense.

What agreement does Agilent have with Prof. Ong – and how do both parties benefit?

We have a Memorandum of Understanding (MOU), which we felt was the right level of depth to begin with – rather than a full-blown research collaboration agreement. So we bring our instrumentation and technologies to enhance the measurements that they are making in their efforts to develop clean energy. We also provide hardware and software training, so that the team can get the most out of our technology.

In terms of the return on investment for us, whenever Wee-Jun’s team publishes a paper, it serves as a good reference for our equipment, how it’s used, where it’s used, and so on. People can then follow those protocols and accelerate their own work. We will also co-develop Application Notes – these specifically focus on methodology and data analysis which will allow other scientists to better understand the analytical process.

What tips do you have for getting the most out of a collaboration?

You can never force a collaboration! I think there needs to be a chemistry between the people you’re working with to build a productive relationship and really get the most out of the partnership. Why? Because a truly successful collaboration requires a willingness to share information and take some risks – and that demands trust.

I’d also suggest starting small – something that can be achieved in a reasonable timeframe. That helps to cement the relationship and demonstrate to investors and stakeholders that you can succeed. From there, you can expand to deepen the partnership – perhaps be a little bolder. There is also an increasing requirement for an industrial partner as part of government grants to academia and these early successes help to provide the evidence of a solid partnership and aid greatly in the chances of getting the grant awarded.

What do these sorts of collaborations mean to you personally?

I certainly enjoy the job, but there are plenty of challenges – seeking out potential partners, the planning involved in putting together an agreement, gaining approvals, and so on. But it is very rewarding when a collaboration comes to fruition. And you do feel as though you are indirectly facilitating impactful research. In the case of Wee-Jun’s research, whether it be producing clean hydrogen from plastic waste or powering fuel cells, the potential is huge and I think it’s going to snowball. I’m excited to see what he and his team can achieve in the coming years.