George Perkins is the leader of mass spectrometry software and applications at PerkinElmer. After gaining a BSc he joined Pfizer to beginning a 22 year association in which he was involved in many areas of mass spectrometry, eventually heading up mass spectrometry NMR and open access. In 2011, George joined Hoffman-La Roche as head of mass spectrometry and purification. George’s work in mass spectrometry, specifically in structural identification using accurate mass as well as automation and open access, has been published on numerous occasions.

How can we rapidly detect economically-motivated adulteration of food and deter fraudsters from committing future crimes?

Food fraud has received increased attention in recent years, in part due to the highly publicized scandal in China in 2007 when melamine was added to pet food and infant formula (1), coupled with this year’s discovery of rat meat disguised as lamb and horse meat in beef (see “How to Beat Cheat Meat”). In the melamine case, opportunists exploited the long-standing system of payment for dairy products. Rather than payment by weight, the dairy industry has paid farmers and suppliers based on protein content for more than a century. Protein content is invariably measured by 19th century methods – Kjeldahl digestion or Dumas combustion – both of which measure nitrogen content and relate it to the amount of protein using a correction factor. The addition of high-nitrogen content compounds to dairy products generates a higher protein content reading and, hence, a higher price. Unfortunately, the added melamine crystallized in the kidneys of both pets and babies, affecting an estimated 300,000 infants, at least six of whom died.

Food fraud is not a new problem; adulteration of wines and spices was widespread in ancient Rome. Ahead of the melamine crisis, the impact of food fraud was mainly economic in nature and less newsworthy. The health impacts in China changed that perception and increased the focus of regulators and food processors. Now, industry leaders concern themselves over adulteration regardless of whether the adverse effects are to health or economics.

A major form of food fraud is counterfeiting, which takes a number of forms:

- Species substitution, for example, passing off mixtures of low-cost juices as high-cost juices.

- Incorrect organic claims, for example, labelling conventional milk as organic.

- Faking food provenance, forexample, selling Indonesian vanillaas Madagascan.

Traditionally, liquid chromatography (LC) or gas chromatography (GC) have been combined with mass spectrometry (MS) to detect marker compounds as indicators for authentic or counterfeited products (2). An issue with these techniques is that they require a certain amount of sample preparation before analysis, such as homogenisation, extraction and clean up. This is then followed by lengthy separation time on a column before a result can be elucidated. The combination of direct sample analysis (DSA) and time of flight mass spectrometry (TOF MS) offers a rapid and simplified alternative. The technology allows for liquids or solids to be directly ionized into the mass spec without sample preparation or chromatographic separation. Powdered samples can be analyzed in a capillary tube with liquid samples pipetted onto a steel mesh and then analyzed. Food-related samples from any source, natural or artificial, organic or conventional, contain a large number of components. The TOF MS allows for very accurate measurement of the mass of a given component in the mixture generated by the DSA. This makes it possible to identify, with a high degree of certainty, specific marker compounds that detect food fraud, without the need for prior separation. Combined with simple traffic light software that allow users with less familiarity with the technology to run it, this makes analysis of food fraud both more effective and more user friendly.

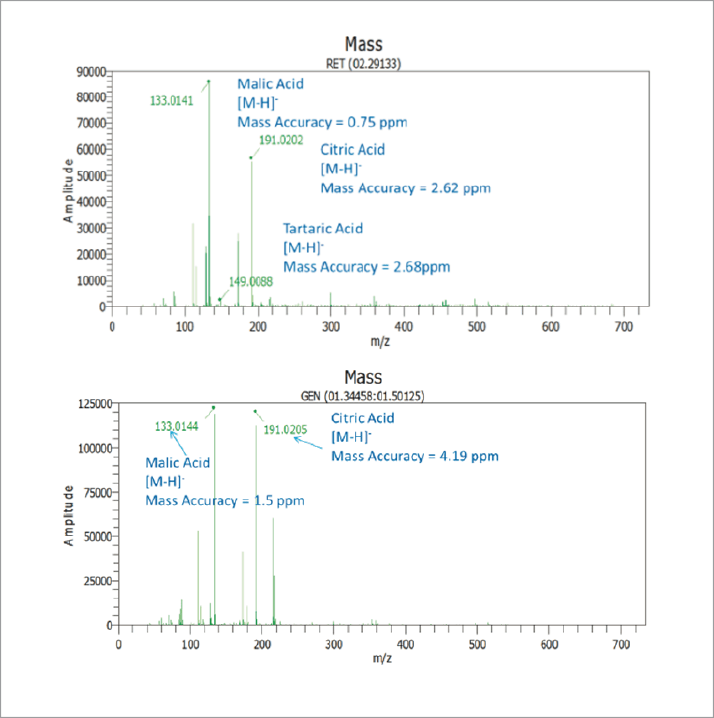

Pomegranate juice has become popular in recent years, in part because of the perceived health benefits of its antioxidant compounds. Consumers increasingly prefer pure pomegranate juice over blends of pomegranate and other juices, although blended juices (with apple or grape) are more prevalent in supermarkets due to their lower cost (pomegranate juice is 5-10 times more expensive than apple or grape juice). A common fraud is to mislabel a blended product as pure pomegranate juice. Moreover, pomegranates are usually grown in countries with a tendency to produce high volumes of fraudulent foods, for example, Iran, Iraq and Georgia. Employing rapid and accurate detection techniques helps ensure that food processors and retailers can be confident in the authenticity of the products they buy and offer customers. A common method of pomegranate juice adulteration is the addition of grape juice. Using the DSA TOF MS, the presence of even one percent grape juice in pomegranate juice can be detected by the presence of a small tartaric acid (2,3-dihydroxybutanedioic acid) peak (see Figure 1). Tartaric acid is absent in 100% pure pomegranate juice so the presence of tartaric acid indicates adulteration with grape juice.

The premium price of organic milk makes it a target for fraudsters. As such, regulatory bodies set strict rules on what constitutes organic milk. The US Department of Agriculture demands that organic milk must be:

- Antibiotic free

- Bovine Growth Hormone (BGH) free

- Pesticide free (3)

- Produced by cows that have had a diet of at least 30 percent pasture grass during a mandatory grazing season of no less than 120 days (4)

This work has shown that detection of marker compounds in combination with fast, minimal sample preparation techniques solves a number of food adulteration and authenticity problems. DSA TOF MS, with its ability to directly analyze solids, liquids, and powders, makes it an ideal technology to analyze multiple food types for known food fraud issues. Complementing this technology will be techniques to screen for new, undocumented adulterations – for the next melamine. These techniques use non-targeted screening, which, despite not having the sensitivity of TOF MS-based techniques, can alert a food processor if their incoming ingredients are outside the norm and should be stopped from entering the processing line. It is conceivable that with non-targeted techniques, such as IR or UV supported by chemometrics at the goods-in bay and DSA TOF MS in the lab, novel adulterants can be stopped and then quickly identified without any danger of them reaching the final product and, ultimately, the consumer. Robert J. Packer and George Perkins work in Global Food Solutions Execution at PerkinElmer, Shelton, Connecticut, USA.

Robert Packer is the Food Solutions Development Leader at PerkinElmer. He has a PhD from Imperial College in London, on completion of which he joined PerkinElmer. He worked as an application scientist in the thermal analysis division and as a molecular spectroscopy project manager before becoming a solutions developer for the food market. In this role he has moved from the UK to Connecticut. His current project , to be released later this year, is an analyzer for screening food raw materials for adulteration and counterfeiting issues.

References

- M. Nestle, “Pet food politics: The Chihuahuain the coal mine”, University of California Press, 2008.

- D.A. Krueger, “Composition of pomegranate juice”, J. AOAC Int., 95, 163-168, (2012).

- spryliving.com/articles/organic-milk-basics/

- See Link

- W. Vetter and M. Schröder, “Concentrations of phytanic acid and pristanic acid are higher inorganic than in conventional dairy products from the German market”, Food Chem., 119, 746–752 (2010).

- A. Carpio et al., “Differentiation of organic goats milk based on hippuric acid content as determined by capillary electrophesis,” Electrophoresis, 31, 2211-2217 (2010).