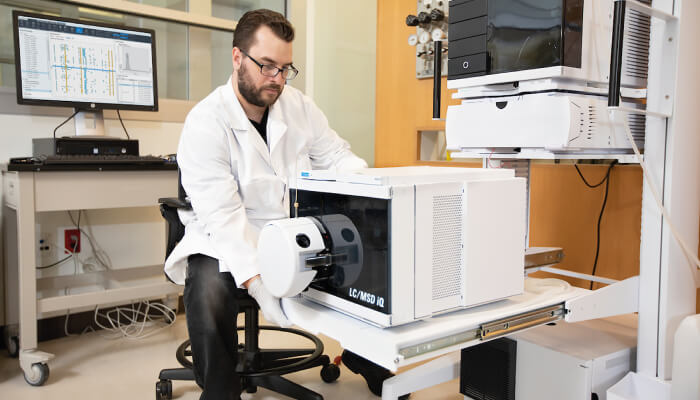

In May, we delved into the results of our survey on liquid chromatography trends and found several barriers to adoption of mass detection in routine analysis – in particular, the complexity, unplanned downtime and cost of ownership. The new Agilent InfinityLab LC/MSD iQ System was designed to help fill these gaps. We spoke to one man behind the machine – Shane Tichy, R&D LC/MS Single and Triple Quadrupole Manager, Agilent Technologies – to learn how the new system can push LC-MS into uncharted territory.

My career in mass spectrometry (MS) kicked off with a summer undergraduate research project, where I immediately fell in love with the instrumentation. I pursued a PhD at Purdue University in a group developing mass spectrometers for research purposes. I then took a position at Texas A&M University as a Research Scientist and was introduced to commercial MS technology for the very first time. After several years in academia, I moved to industry and I have been at Agilent for the past 12 years. Now, I’m responsible for leading an amazing team that conducts research and develops innovative systems – exactly what I dreamed of doing.

I have been the Program Manager since inception. You may be surprised to know that the technology was developed in a relatively short time frame – a little over a year. To get there that fast, we leveraged multiple innovative technologies from the Ultivo Triple Quad – but we also had to focus on ease-of-use, streamlined maintenance processes and optimized manufacturing. And that meant we essentially had to re-think the entire mechanical design and the layout. One reason for the rapid progress was our clear vision of what we wanted the LC/MSD iQ to be.

As confirmed by the survey, increasingly strict regulatory requirements mean that HPLC analyses often need more specific and selective detection than can currently be achieved with UV-Vis. Meanwhile, the technology all around us continues to become more integrated, easy to use, productive and self-aware – we wanted to bring all those qualities to LC-MS, to lower the learning curve and improve lab operations (overcoming some of the barriers identified in the survey).

Our biggest challenge was the need to rethink all the mechanical connections and the electronic architecture; we knew that we had to enhance the maintenance and serviceability by designing a modular system. Users don’t want to unstack the LC components sitting on the mass spectrometer to do routine maintenance, so we developed a cablefree, centralized, interconnected board, which can be accessed from the side of the system.

Our goal was to get to a point where a user can walk up, put a sample in the autosampler, and, within a few taps of a touchscreen, be ready to run the analysis – and I’m pleased to say we’ve achieved that!

Missed the infinityLab LC/MSD iQ launch at ASMS? Click here to view our three-part in-the-lab demo series.

We believe the LC/MSD iQ will appeal to users in a range of markets, including drug development, chemical synthesis, academia and food production. However, we believe that the system will be most quickly adopted by pharmaceutical laboratories working on reaction monitoring and in QA/QC settings.

The big advantage of moving to mass detection is achieving more specific and more selective detection than is currently possible with UV. The InfinityLab LC/MSD iQ makes mass detection much more accessible to users who are new to MS. The launch of this systems points the way to a future where mass detection is no longer the exception for HPLC but is considered the standard analytical technique.

The early customer feedback has been very positive in terms of the analytical capabilities, the instrument health tracking and the simplicity and speed of the maintenance process. The LC/MSD iQ allows managers to predict and schedule maintenance in a way that optimizes their lab operation and minimizes downtime, which dovetails neatly with our overarching focus on greater efficiency in the lab (Click here to find out more).

The team and I are extremely excited and honored that our system was launched at the most important MS event in the calendar. We believe that we have developed a very innovative product that is going to do well in the market because we are addressing real customer needs. The journey from inception to release can be a rollercoaster ride of emotions – from excitement to tearing your hair out and back again – but the feeling of launching something new onto the market is a real high! I never thought that I would have the opportunity to work on such cutting-edge products; I love it, and I’m already looking forward to the next challenge.