Laboratories are constrained by requirements for extremely high sample throughput and rapid method development. How can a GC method-modeling program that was initially aimed at advanced users be repurposed to provide quick solutions to difficult separations?

Restek’s EZGC line of software tools for chromatography has a history dating back to the release of the original Pro ezGC DOS program, built in collaboration with Analytical Innovations in 1992. The first Pro ezGC software made it possible to predict retention times and optimize chromatographic methods without the need to analyze compound sets under many different conditions. Built in the era of Intel 486 CPUs, the Pro ezGC tool was incredibly powerful for chromatographic modeling for its day. It contained algorithms that were capable of computing thermodynamic retention indices and complex chromatographic models quickly and accurately, while contending with the challenges of limited computer memory and space. Two products were initially available: the basic ezGC application, which modeled chromatographic separations based on pre-generated libraries of thermodynamic retention indices, and the Pro version, which allowed the user to create new libraries. The Windows version of Pro ezGC software was released in 1994, and the product was built using some of the first object-oriented software for the Windows graphical user interface (GUI). And while the software was powerful for its time, it still had to contend with the limits of the systems it could run on. The thermodynamic index libraries were limited to 99 compounds, and the compound names themselves had character limits. In addition, the chromatographic models that were generated were limited to 100 compounds. But within those limits, the Pro ezGC program was able to perform impressively, evaluating thousands of models in a matter of minutes. It was this power that was employed in labs around the world, including internally at Restek, where it is still used for the development of applications as well as optimizing new products. (The majority of the chromatograms found on our website were developed using Pro ezGC software.)

One notable application of the Pro ezGC program was the determination of the phase, film thickness, and conditions for columns that would eventually be used in the Philae lander’s GC instrument. Robert Sternberg and his GC team at LISA, the Laboratoire Interuniversitaire des Systèmes Atmosphériques of the University of Paris XII, needed to develop methods to separate origin-of-life compounds in support of the European Space Agency’s (ESA) Rosetta mission in its rendezvous with comet 67P/Churyumov-Gerasimenko (see tas.txp.to/0615/rosetta for more information). LISA had very specific requirements in determining the columns to be included in the Philae lander. Power restrictions limited the analysis time as well as the average temperature of the analysis, and columns with a small inner diameter were needed to limit the consumption of carrier gas. Using Pro ezGC software they were able to select the stationary phases they would need by simultaneously adjusting film thickness, temperature, column length, column internal diameter, and flow. The results of the work required that Restek manufacture custom columns based on LISA’s Pro ezGC predictive modeling. The models closely matched the manufactured columns as published back in 1999 (1). To be effective, Pro ezGC software requires the user to have a solid understanding of GC parameters. For example, the user must understand that lower starting temperatures are necessary when performing splitless injections, but a higher starting temperature is possible when operating in the split mode. Indeed, the user must answer several questions in advance because all parameters are chosen by the user, not the software; for example, is there a polarity mismatch between the compounds and the column? What carrier gas will work best with the instrument, and what is its maximum ramp rate? In other words, the speed of the Pro ezGC program is not helpful if injection port conditions, carrier gas choice, and GC limitations are not clearly understood. As the years passed, the Windows platform changed significantly. Today, to run the Pro ezGC program in Windows Vista and 7, you need to use virtual machine. And it will simply not run in Windows 8. This new reality – coupled with the complex interface and the library size limits – was a key driver in our decision to update the software.

In 2010, Neil Mosesman (head of Restek’s Technical Service department at the time) convened a meeting with the Analytical Innovations team to determine a way forward for the Pro ezGC tool. Many ideas were proffered, from simply redoing the application for Windows 7 and above, to moving the whole application online. Funnily enough, the main concern voiced had nothing to do with the platform we chose, but instead with the target market for the new application; Pro ezGC software was not designed to help customers who work in high throughput labs that require instant column recommendations with column conditions. The big question became: how do we re-purpose this admittedly complex tool to meet the needs of a new user base? Neil stepped in to help focus the problem: “What one thing do all of these users have in common?” The answer? “A list of compounds that must be separated.” Suddenly, we had a solid basis for a new proposal; we want to take a list of compounds from the user and return a modeled result – with no user intervention. The model will be a “good” result, where good is defined as our best attempt to meet or exceed baseline resolution for all compounds requested on an appropriate phase. The resulting model would include a column recommendation (phase and dimensions), basic instrument conditions, and a recommended oven temperature program. The idea quickly caught on with the group and was reflected in our final project proposal. Of course, implementing the idea was far easier said than done. Nearly two years of planning and development involved migrating code from the Windows platform to run on Linux web servers to take advantage of the increase in processing power and memory. In addition, we created and refined the tool’s business logic and algorithms so that the software could produce a result quickly enough to match expectations set by the fast response times of modern websites. And even with the pared down interface we were planning, there were significant usability issues that we needed to address. One hurdle was compound nomenclature, which required that compound names be routed through a synonym database to aid compound matches. Compounds could have up to a dozen different names and the program would have to accommodate any one of them. To further help customers hit the target, all the compounds in our database needed to have a phonetic key to help with alternate spellings or misspellings. And for customers who did not find their compounds matched in the Pro ezGC library, we performed a search in our chromatogram database as a backup (which was especially helpful with permanent gas requests where the best solutions are found on porous layer open tubular (PLOT) columns).

The end result – rebranded as the EZGC chromatogram modeler – was made available as a web application so customers would always have the latest version and never have to worry about the software becoming out-of-date. And the multiple dialog boxes and form fields of the previous interface were pared down to a single input field (see Figure 1). Users need only enter a list of target analytes into the field and the software returns GC column and condition recommendations that are optimized for the user’s specific analyte list, providing a significant leg up on method development. The second app in the suite of tools – the EZGC method translator and flow calculator – was developed at the request of Jack Cochran, Director of New Business and Technology, who, along with Tom Kane, Director of Research and Innovation, oversaw the development of the tools and provided great advice on the interface and behavior of the application. The method translator was developed to bring back some of the functionality that was left out of the chromatogram modeler, while simplifying the interface and bringing a modern look and feel to a tool that chemists may use every day in their work. Customers could now take the conditions from a modeled chromatogram and tailor them to their needs while maintaining the elution temperature profile of the original model. We also paired the method translator with a flow calculator, and added the ability to move data between the two interfaces. The combined tool has many potential applications for method optimization and translation; it can be used to establish proper conditions when switching carrier gases, speeding up analyses, changing column dimensions, or moving from an FID to an MS detector.

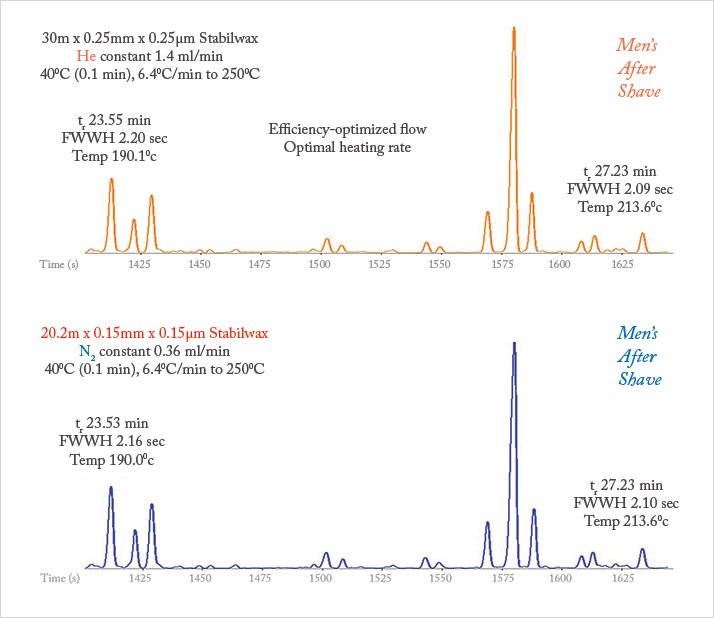

Restek’s method translator was recently used by our own Jaap de Zeeuw to validate an idea that came to him in a dream (Jack says that Jaap does some of his best work while asleep!). The dream, which woke him up at 3am one night on a business trip to Singapore, was that using nitrogen on a 0.15 mm column should allow for a clean translation from a 0.25 mm column using helium, without needing to alter the temperature program or increase analysis time. He quickly tested and tuned his idea/dream in the method translator and then passed the idea by Jack, who followed up that weekend with some experiments on both a polar Stabilwax column (see Figure 2) and a nonpolar Rtx-CLPesticides column to verify the solution the software provided. Nearly identical analyses were obtained using nitrogen and the translated method, proving just how effective the software can be in aiding method development – or confirming the prophetic nature of dreams. The journey from the powerful (but complex) Pro ezGC program to the newly reconfigured (and simplified) EZGC method development software has been an exciting one. Through the collaboration of analytical chemists and software developers, we were able to boil the input requirements of the original program down to a single essential question – what compounds do you need to separate? From there, further method optimization is possible, giving GC users a fast, easy-to-use tool for solving real-world problems.

Chris Nelson is a member of the web development team, Jaap de Zeeuw is International GC Specialist, Jack Cochran is Director of New Business and Technology, and Chris English is Innovations Laboratory Manager – all at Restek Corporation, Bellefonte, Pennsylvania, USA.

References

- C. Szopa et al., “Gas Chromatography for In Situ Analysis of a Cometary Nucleus: Characterization and Optimization of Diphenyl/Dimethylpolysiloxane Stationary Phases”, J. Chromatogr. A 863, 157 (1999).