Analysis of Elemental Impurities in Naphtha by ICP-MS according to ASTM D8110-17

contributed by Analytik Jena |

Challenge

Analyzing volatile organic solvents often associated with plasma destabilization, signal drift due to cone clogging and carbon-based polyatomic interferences.

Solution

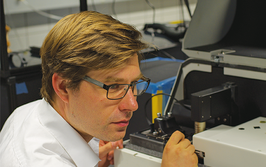

PlasmaQuant MS with cooled spray chamber, Nitrox gas accessory and hydrogen reaction gas in interference management mode for accurate and precise analysis of organic solvents.

Introduction

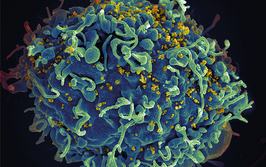

Naphtha is a petroleum fraction containing C5-C12 hydrocarbon compounds, which is used in the petroleum industry for gasoline formulation and in the petrochemical industry for producing a wide range of chemical products such as ethylene, propylene, and p-xylene. The monitoring of trace metal contents in naphtha is important for a number of reasons[1]. In fuel production, the presence of metals such as calcium, magnesium, sodium, and potassium can form hard deposits and create excessive wear on the engine components. On the other hand, the presence of nickel during the cracking process can poison the expensive catalyst, while vanadium causes corrosion problems. During the refining process, the release of toxic metals such as lead, mercury, and arsenic has to be monitored and minimized since they are of environmental concern.

For the analysis of small impurities in naphtha, lowest limits of detection need to be achieved which makes ICP-MS the technique of choice. However, due to the complex nature of naphtha, the analysis by ICP-MS requires special attention to minimize the formation of carbon deposits on the sampler and skimmer cones and avoid the instability or even the complete extinction of the plasma due to organic vapor overloading. Interferences due to polyatomic species, originating from the carbon matrix and plasma, must also be considered and eliminated.

Log in or register to read this article in full and gain access to The Analytical Scientist’s entire content archive. It’s FREE!