Food Analysis at Your Fingertips

They’re small, they’re fast – and they could soon be in our pockets. We profile two innovative Horizon 2020 food projects that combine analytical technology with smartphone portability to put food analysis into the hands of consumers. The future is (almost) here – and it knows what’s in your food.

Shoot First, Ask Questions Later

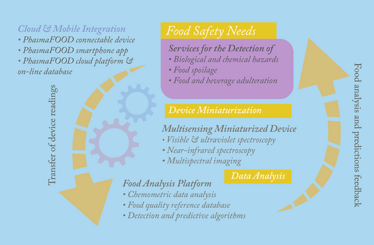

Food researchers are joining forces with hardware and ICT developers and mobile phone app writers to build a new type of scanner. Integrating three sensor devices with advanced software, the PhasmaFOOD will provide miniaturized and on-the-spot analysis for the detection of food spoilage and food fraud.

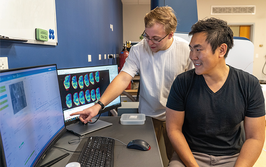

The whole idea of PhasmaFOOD is to combine different light sensors into an integrated scanner system and build a consumer app around it to make a new generation of light food scanner. So-called heterogenous photonics is the ultimate hardware goal, which basically means that all the elements of a photonic system are fabricated on a single chip to meet size and cost requirements. The device will host three sensor types: two spectrometers and one micro-camera. In addition, three light sources will be integrated with the device to support its sensing functionality. A dedicated PhasmaFOOD mobile app will allow end-users to interact with the device, and the captured data will be communicated via wireless mobile networking to the PhasmaFOOD backend. Analysis results will immediately be sent to users, who will be able to access them at any time and from any location.

Why has portable food analysis suddenly become such a big thing? I think in one way it’s very much technology driven; until now, it was not possible to make a chip with an infrared sensor small or cheap enough. It was also not possible for smartphones to operate in such a way. The people making smartphone technology five or six years ago already recognized that people would be using their phones to a much greater extent in the future. Me? I can’t remember how good my phone was five years ago – actually, I don’t even remember if I had a smartphone! But the interest in food analysis is also consumer-driven; people are suddenly more interested in “scanning” their food – the idea of doing your own analysis, in a simple way, triggers something in people.

A need for something new

When I started here at RIKILT, there were many research position vacancies available. I’d already worked with mass spectrometry during my PhD and wanted to try something new. I’d heard a little about scanners, and thought, “Why not go in that direction?” The fact that the technology would be used by people at home rather than stay in the lab very much appealed to me. Most of the time, during my PhD, this was not the case; you did fundamental, very technical research, which I didn’t always find very satisfying. I really like to make things which will be used in real life.

So when I started working here about three years ago, I did some preliminary work on chicken meat. Using a very simple infrared scanner, we attempted to find the water and protein content of the chicken, with the aim of finding out more about how (and how long) it had been stored. The consortium of PhasmaFOOD (George Koutalieris, from INTRASOFT International and Paraskevas Bourgos, from WINGS ICT) began looking for expertise on testing the PhasmaFOOD scanner – and that’s how I got involved.

I started acquiring advanced miniaturized IR sensors from Viavi Solutions (formerly JDSU). We began partnering with more companies, and the publicity on food scanners started to build. People started to understand the objective: to revolutionize the use of infrared. It was the beginning of a movement from the lab (a controlled environment) to something completely uncontrolled; from very exact databases to big databases built into an app by non-specialists. Of course, infrared sensors are already being built into phones, but there are still many things you can’t do, such as measuring allergens, gluten, lactose or toxins.

Current food scanners – Spectral Engines (the winner of the European Commission’s Horizon 2020 food scanner award), SciO (ConsumerPhysics), or TellSpec (the runners up) – are all based on near infrared (NIR) technology. However, NIR spectroscopy is actually somewhat limited in this application; you can scan the macrocomposition of products and even find components that are minimally present (0.1–1 percent). But NIRS struggles to measure very low concentrations of compounds or food spoilage, so more advanced applications are out of reach. We need more information, and that’s why we need a new food scanner.

Perfect sense

Our device works much like any vibrational spectroscopic sensor and must be “trained”. For example, if you want to know the moisture content of a piece of meat, the sensor must be presented with different reference samples with different concentrations of moisture within an acceptable range to build a spectral database and a multivariate statistics-based algorithm. If the sensor can actually measure moisture content in a new sample, your model works correctly. If not, you must expand the database to cover more variation in the food samples you present to the sensor. Variation is always a problem with food analysis; to build a functional database, you have to cover a significant amount of natural variation within a given food product. Unlike the pharmaceutical industry, which tends to have narrow concentration windows for all chemicals present, potential variation in food sometimes feels infinite.What is the impact of a different country of origin, a different farm – or even a different cow?

The project started at the beginning of 2017 with the refinement of the hardware, so the sensors and illumination sources are already available. Design of the prototype – how the electronics, hardware and casing will fit together – is already underway. Designs for the cloud database and the apps have begun, and the team has also performed business case and user case analysis. The main and current analytical task is making reference measurements and using that data to build spectral databases. We are (slowly) testing the sensors for the proposed applications, namely the detection of:

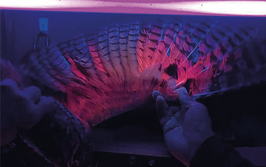

- mycotoxins and aflatoxins in nuts and grains;

- food spoilage and shelf-life prediction;

- food fraud and adulteration.

We decided to focus on these three areas because they are particularly tough nuts to crack for food scanners (no pun intended) – and also because of the potential societal impact. Mycotoxins and aflatoxins are very much of interest to the general public because of their potency, but current NIR food scanners fail to reach the typically low concentrations. Spoilage is relevant for people at home, so that they can estimate the age or expiration date of their product (again, very hard for infrared scanners), which could help to reduce food waste. Food fraud – finding melamine in milk or analyzing mixtures of different meat – are also out of reach for NIRS-based scanners.

We are also looking at alcoholic beverages because it’s so topical, especially in countries where there are problems with fake drinks or those that contain toxic compounds.

Food for Thought

Michel Nielen is co-chair of the RAFA 2017 food analysis conference in Prague. Here, he tells us what’s on the menu this year.

Can you give us a roundup of RAFA 2017?

RAFA is the leading biannual conference on recent advances in food analysis. In November we expect 800+ participants in beautiful Prague. We usually have a large audience and speaker lineup comprised of people who are active in food contaminants (pesticides, antibiotics, POPs), natural toxins and fraud, but we will also cover growing trends in the world of (advanced) food analysis. Food fraud in particular is an ever increasing issue; a couple of years ago, we had only one session about food fraud, but now it is one of the cornerstones of RAFA.

What’s new this year?

Human biomonitoring is one very interesting new topic that will be covered in RAFA 2017. In current duplicate diet studies, half of the food is consumed, the other half sent to labs for food analysis, so they can measure contaminants or other compounds that have been ingested. You might also collect samples like blood or urine to find a link between analysis of the product and the consumer/consumption. Nowadays, people are searching for alternative means of finding consumption data with contaminants or nutrition value patterns. There is an emerging trend to use head hair specimens, which is borrowed from the forensic field, where hair has been used for drug testing. Your head hair, which grows 1cm a month, represents a chemical archive – the chemical composition of 1cm of your hair correlates with your food (and drug) intake from the last month. It’s an entirely new concept for the food analysis field. In fact, it’s relatively novel to see people trying to retrieve food consumption and contaminant exposure data from urine and blood. And so, for the first time, we decided to organize a session called “Human biomonitoring related to food” – and we have arranged some high profile speakers.

In food analysis, the focus is traditionally on foods, food products and intermediate products or raw materials. Such samples are being analyzed in labs in line with legislation; for example, maximum residue limits. But we also need to know more about food intake and consumption patterns, to understand the risk of exposure to food-related hazards.

Are you running a session on portable food sensors?

Yes, the PhasmaFOOD/FoodSmartphone guys will take the lead in organizing an oral session about smart sensing. There’ll also be hands-on demos in a dedicated “smart lab”, where people can start playing with food scanners and smartphones and do some testing themselves.

What are you particularly looking forward to?

I’m looking forward to the food fraud sessions, as there is a lot of interesting research going on. I’m also very interested in natural toxins; mycotoxins have been studied for many years, but there will be focus on plant toxins, marine toxins and bacterial toxins as well. From the more practical side, multiple pesticide analysis is always a highlight. At RAFA 2015, vendors had instruments in production doing multiple analysis of hundreds or even thousands of food contaminants, in a single analytical run; it’s always exciting to look forward to major improvements in mass spectrometry technology both from researchers and instrument vendors.

Recipe for success

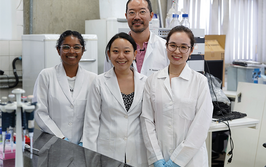

Multiple partners have come together for the PhasmaFOOD project. We have the leading European IT Solutions and Services Group (INTRASOFT International), an ICT company (WINGS ICT), and cognitive networking lab VizLore, which builds apps and interactive data management systems. Then we have the hardware people from Fraunhofer IPMS, The National Research Council of Italy (CNR), the University of Rome and the Free University of Berlin, who are involved in data compression and communication between different systems. Finally, the Agricultural University of Athens and RIKILT Wageningen University and Research are testing the sensors. Wageningen is quite well known for food research, so it’s quite a logical choice!

Clearly, the consortium comprises academic and industry partners – and that is, in fact, a requirement for such EU-funded projects; if you submit a purely academic proposal, you would never get a grant. Indeed, there is close to zero fundamental research – everything is aimed at “getting it out there.” We have to be at a certain technological level at the end of the project. And though the high-level view of PhasmaFOOD appears pretty straightforward – decide on objectives, make a design, build a prototype, and test it – from a project management point of view, it is highly complex, with many teams working simultaneously on different aspects. For example, we have to make measurements with sensors that are not yet mounted into a prototype, so that as soon as they are mounted, the database will be partly ready.

In PhasmaFOOD, we are going for immediate impact by making the different sensors quite defined. We want give someone who is completely untrained the capability to take a scanner anywhere, and just “point and shoot” – it’s a completely new way of using a very old technique.

Yannick Weesepoel is Researcher, Food Authenticity – Food Scanners, RIKILT, Wageningen University & Research, the Netherlands.